Project Description

A Network of Company’s Using Fill-Free Automation to Improve Efficiency

[gslogo id=2]

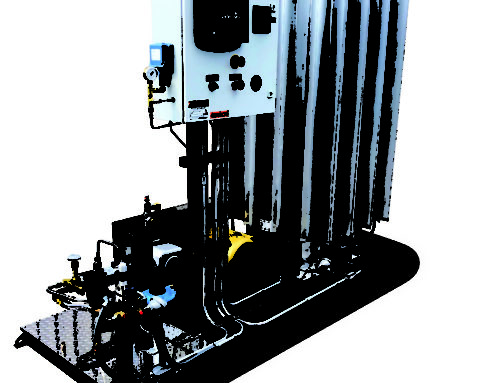

Fill-Free Automation

1.0 (Simplex) & 1.5 (Duplex), Single Product (Pure Gas) Semi Automated System – Pressure Temperature

This system will sense and compute temperature, pressure and vacuum, notifying the filler when the cylinder is full. Freeing your filler to tend to other tasks while the fill process is cycling. Our System is PLC controlled and includes a color touchscreen control screen.

2.0 (Simplex) & 2.5 (Duplex), Mix Gas (Inert) Semi Automated System – Pressure Temperature

These systems will sense and compute temperature, pressure, vacuum, notifying the filler when the cylinder is full. Freeing your filler to tend to other tasks while the fill process is cycling. Our System is PLC controlled and includes a color touchscreen control screen.

3.0 (Simplex) & 3.5 (Duplex), Mix Gas (Inert) Semi Automated System – Gravimetric, (Fill by gram weight)

These systems include all of the benefits in Fill-Free 2.x + a gravimetric fill enclosure, reference cylinders and scales for 2 zones.

Automation, Fill-Free™ – 4.x & 5.x, The CryoVation “Fill-Free” Fully Automated System 4.0 will sense and compute temperature, pressure, vacuum and open and close valves automatically. Fill-Free 5.0 brings the addition of gravimetric components and precise mixing.

Automation brings accuracy as well as freeing your filler to tend to other tasks while the fill process is cycling. Our system is PC based so we can store batch information and access remote monitoring, so you could login from anywhere and see what was happening.

For more information, see the technical information below.

If you are looking for Parts, Accessories or valves, see our parts site thecryoshop.com